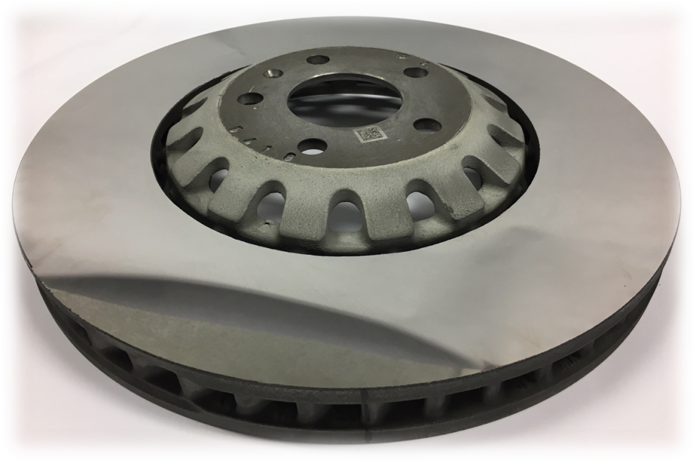

Brake discs with

Hard coating (EURO 7)

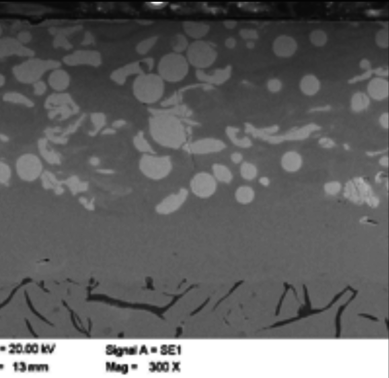

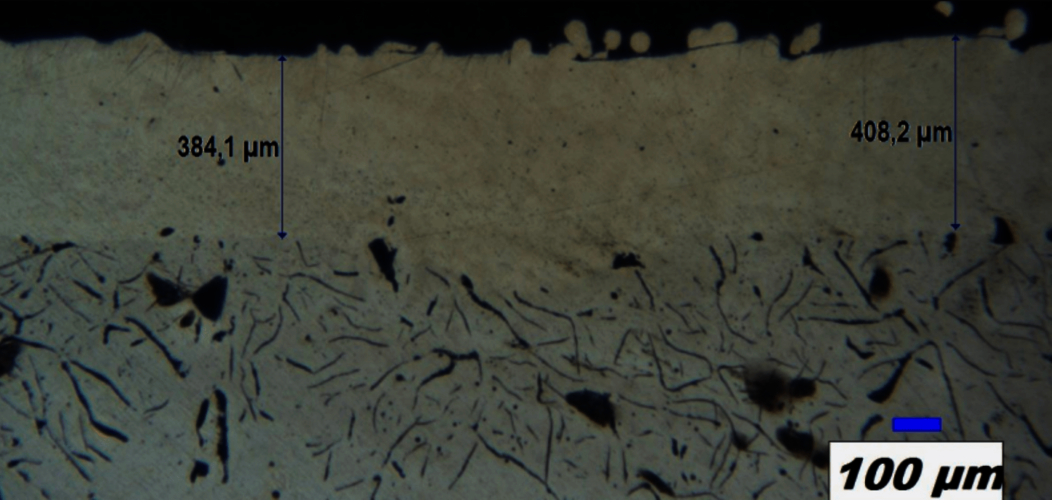

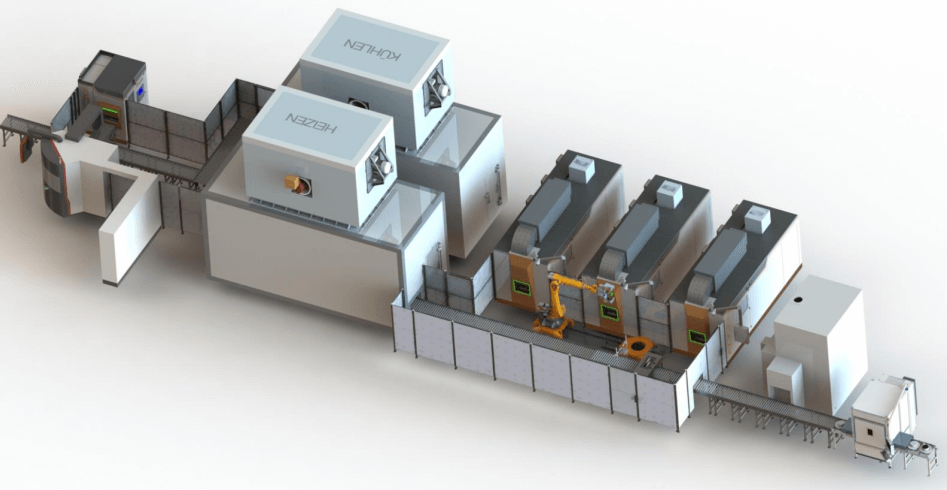

The ROCATRON hard coating (EURO 7) is a coating that which brings the following solutions:

Extension of the service life of the brake disc and, if necessary, the brake pad

This is accompanied by an extension of the service intervals

Reduce CO2 emissions during production and driving

Fulfillment of the planned EURO 7 standard with regard to fine dust