Brake Discs with long-term

Corrosions Protection (LCP)

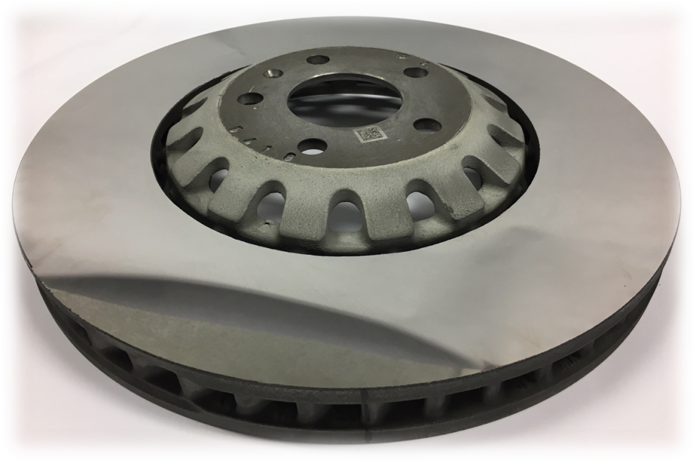

ROCATRON long-term corrosion protection (LCP) was developed for brake discs and use in electric vehicles. With the aim to protect brake discs for much longer use in vehicle than today.